OLI proudly presents the Scale Kinetics and Inhibitor Optimization Tool (SKIT) in Version 12 of OLI Studio. This cutting-edge innovation merges advanced thermodynamic modeling capability with the nucleation kinetics modeling, designed to predict the onset of scale buildup and proactively devise mitigation strategies This kind of tool is essential in upstream oil & gas, geothermal, and water treatment facilities as it enables advanced diagnostics in scaling prevention based on water analysis data. SKIT also allows the selection of appropriate types and precise concentration of scale inhibitors needed to manage the production risks effectively. SKIT integrates several advanced functions, including OLI’s renowned Mixed Solvent Electrolyte (MSE) model which enables scaling tendency calculations, the likelihood of formation of a certain kind of scale, while the classical nucleation theory informs the induction time, the time associated with the appearance of the first crystal phase. Furthermore, a model akin to the Langmuir adsorption model allows the capture of the effects of inhibitor adsorption on the mineral scale surface to procrastinate the growth of the nucleus and hence inhibit the formation of mineral scale. All the parameters associated with the aforementioned models that quantifies the interaction between mineral scale, produced/formation water, and inhibitors are included in

OLI’s chemical databank. SKIT tool includes an “Optimizer” functionality that allows users to adjust model parameters within OLI’s chemical databank to better align with experimental data, whether inhibitors are used or not. This adjustment capability supports blank testing, single inhibitor testing, and mixed inhibitor testing. Additionally, the tool can parameterize the kinetic model for new scaling solids. This regression capability enables companies to build proprietary risk databases, enhancing predictions, incorporating proprietary inhibitors, and introducing additional scales.

Key features of the SKIT tool:

- Facilitates the calculation of induction time for four common scaling minerals (Calcite, Gypsum, Barite, Celestine) both with and without the presence of inhibitors such as HEDP, NTMP, DTPMP, EDTMP, PMA, and PBTC.

- If there is a discrepancy between the OLI model calculations and actual field or experimental lab test data, the SKIT tool enables users to adjust the model parameters to align with experimental trends, using or excluding inhibitors through the “Add Optimizer” functionality.

- The Optimizer functionality within the stream analyzer uses data from water/brine analysis to calculate and compare induction times with laboratory or field results.

- Should the model fit prove unsatisfactory, the tool permits the modification of some, or all parameters related to OLI’s induction time model.

- This adjustment capability is applicable in scenarios involving blank testing, single inhibitor testing, or mixed inhibitor testing.

- The tool also supports the parameterization of the kinetic model for new scaling solids previously not included in the tool.

The scaling kinetics and induction time model integrates Mixed-Solvent Electrolyte (MSE) model with Classical Nucleation Theory (CNT), offering a comprehensive assessment of scaling risks and kinetics. The details of the scaling kinetics and induction time model can be found here. For brevity, let’s simplify the induction time model as follows:

Where as is the calculated induction time from the model, SEP1~5 is Surface Energy Parameters for scaling solids, SCKINT1~2 is Scaling Kinetic Interaction Parameters between inhibitors and solids, SCKMIJ represents Scaling Kinetics Mixing Parameters. These parameters are readily available out-of-the-box for calcite (CaCO3), barite (BaSO4), celestine (SrSO4), and anhydrite/gypsum (CaSO4). Similarly, inhibitors such as NTMP, DTPMP, HEDP, PMLA, and PBTC, widely used for scaling inhibition globally, are also preconfigured for immediate use. Table 1, 2 and 3 provide more details of OLI specific model description and practical significance.

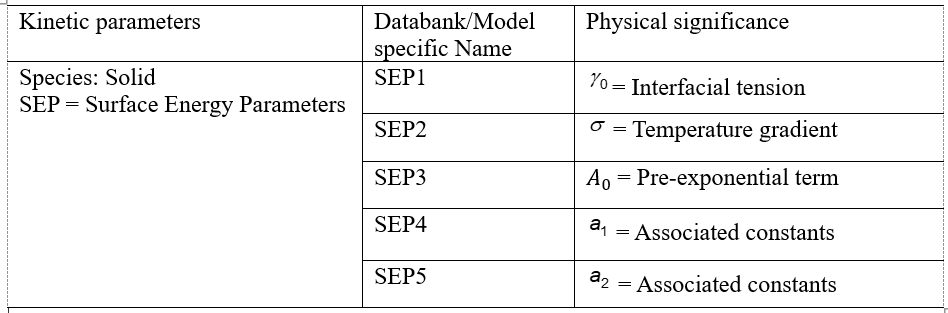

Table 1: Surface Energy Parameters (SEP) available for Optimization.

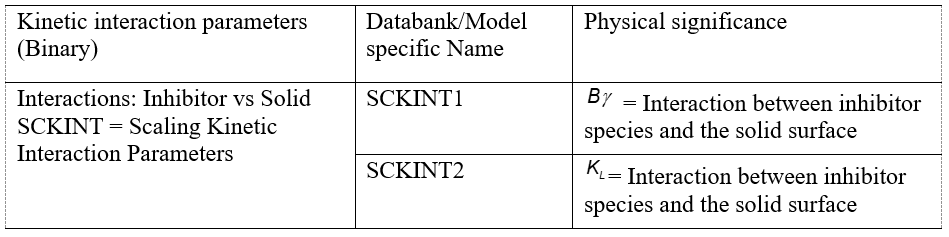

Table 2: Scaling Kinetic Interaction Parameters (SCKINT) available for Optimization.

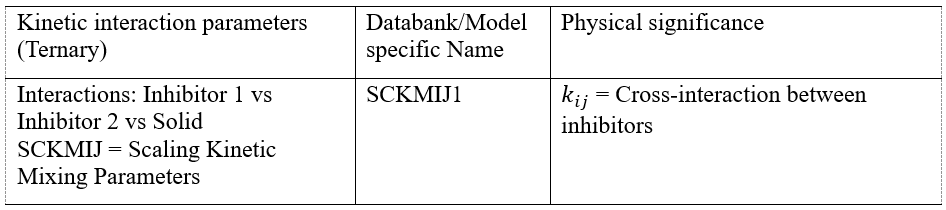

Table 3: Scaling Kinetic Mixing Parameters (SCKMIJ) available for Optimization.

For optimization or data fitting, we utilize BOBYQA as the optimization algorithm from the NLOPT library. BOBYQA, which stands for Bound Optimization BY Quadratic Approximation, is a derivative-free, bound-constrained optimization algorithm. It iteratively searches for a local minimum of a function, making it an effective tool for optimization tasks.

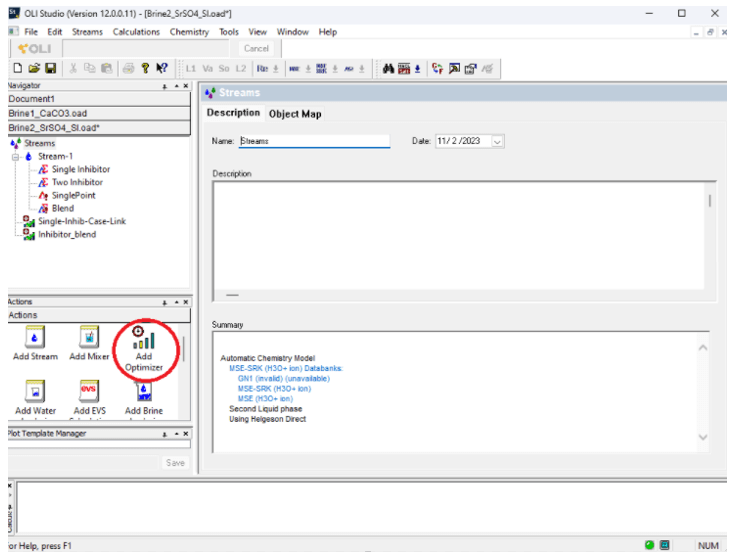

The SKIT tool is incorporated into Version 12 of OLI Studio. Figure 1 illustrates how the “Optimizer” object can be added to the calculation.

Figure 1: Optimizer tool in OLI Studio software platform version 12

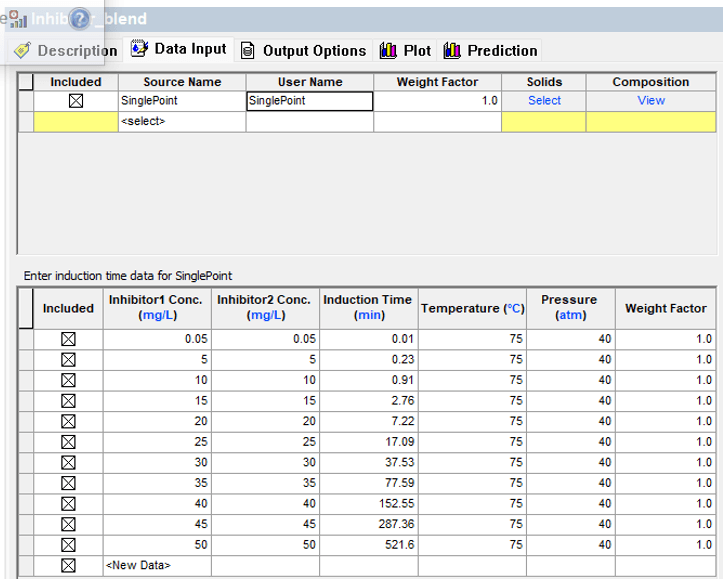

Figure 2 illustrates the data input sections where observed data are tabulated. The optimization process can incorporate various datasets, such as multiple source streams, each with its own data table. Users have the flexibility to assign weight factors to individual datasets or source streams and specify weight factors for individual data points within each table, tailoring the optimization process by customizing the importance of specific data points or datasets. Users can assign any positive number as the weight for their datasets and data points.

Figure 2: Data input window for including field/experimental data under specific process conditions

Additionally, advanced options allow users to select optimization-specific convergence parameters, such as upper and lower bounds, the number of function evaluations, initial values, stopping criteria, and more. If users do not modify these advanced settings, the software’s default selections will be employed in the calculations.

Variables can be marked in three ways:

- Regress: These are free variables subject to variation during optimization.

- Fix: These variables will have a specific value assigned to them, which will remain unchanged during optimization.

- Link to: These variables will be replaced in value by the selected, or linked, parameter. “Link to” is employed to synchronize a particular parameter with others in the model, essentially copying its behavior. When users designate “Link to”, the current parameter is replaced by the parameters they have chosen.

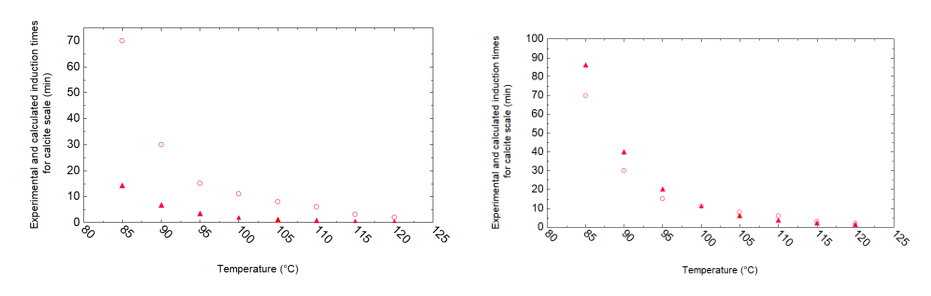

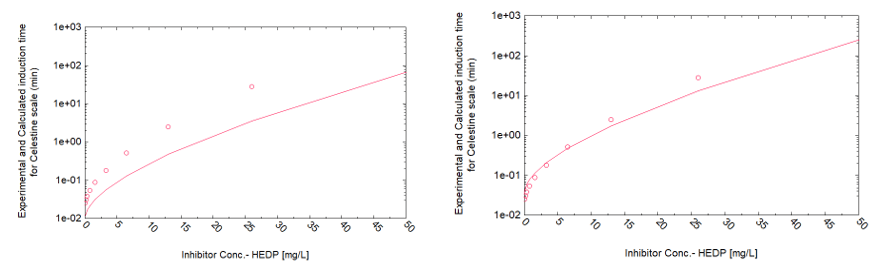

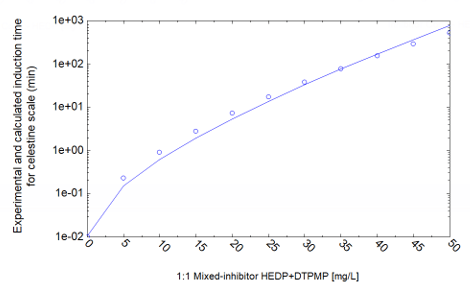

With the SKIT tool, users can create customized local models based on their in-house experimental or field data, integrating their organization’s expertise in scaling treatment with a physics-based model. Additionally, users can benchmark laboratory test data against the physics-based model, allowing for easy reparameterization by incorporating privately acquired data. Figure 3 illustrates Calcite scale formation based on a specific water sample: (a) shows the deviation between observed and calculated data without optimization, while (b) presents the results when kinetic parameters are fitted to match the observed data using the SKIT tool’s optimization functionality. Overall, the plot in Figure 3(b) provides a closer approximation to field observations. Similarly, Figure 4 demonstrates Celestine scale in the presence of HEDP inhibitor for a water sample. Again, Figure 4(b) offers a better representation of the field observations, with the optimized parameters providing a more accurate model approximation. Users can evaluate the effectiveness of single or mixed inhibitor dosages on a specific scale by measuring the increase in induction time across a wide range of operating conditions. Figure 5 shows the experimental versus calculated induction times for Celestine with mixed inhibitors.

Figure 3: Experimental vs. calculated induction times for Calcite scale – (a) without optimization, and (b) with optimization. Open circles indicate field or experimental data, while filled triangles represent model calculations.

Figure 4: Experimental vs. calculated induction times for Celestine scale in the presence of HEDP inhibitor – (a) without optimization, and (b) with optimization. Open circles indicate field or experimental data, while solid lines represent model calculations.

Figure 5: Optimizing induction time with mixed inhibitors for Celestine scale treatment. Open circles indicate field or experimental data, while solid lines represent model calculations.

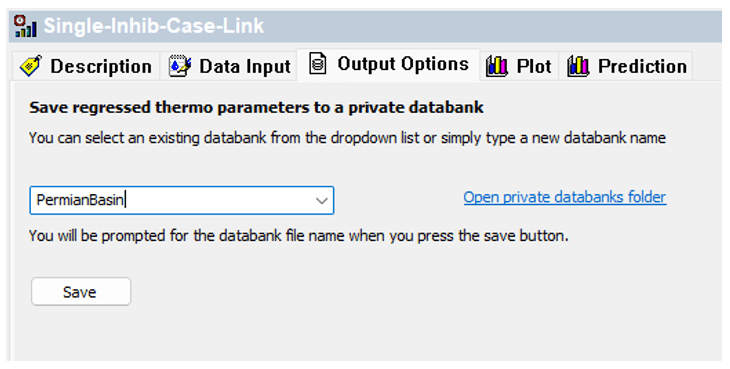

After optimization, once users are satisfied, the optimized kinetic parameters can be saved in a private databank, making them portable. Users can directly include this new private databank in simulations and further modify the parameters through additional optimization. Figure 6 illustrates the option for saving optimized kinetic data in a private databank.

Figure 6: Save optimized kinetic parameters in a private databank for future use.

Additionally, the SKIT tool features a Prediction Plot that provides a comprehensive snapshot of the model using the newly optimized parameters. This Prediction Plot not only visualizes the performance of the updated model but also offers a sensitivity analysis-like perspective. It illustrates the effects of scaling inhibition under varying process parameters, enabling users to understand how changes in conditions such as temperature, pressure, and inhibitor concentrations impact the scaling tendencies and effectiveness of the inhibitors. This powerful feature aids in making informed decisions by clearly depicting the relationship between process variations and scaling inhibition outcomes.

The SKIT tool provides the capability to optimize kinetic data for any new scales beyond Barite, Celestine, Gypsum, and Calcite, if induction time data is available. This feature allows users to expand the tool’s applicability to a broader range of scaling issues. By inputting induction time data for the new scale, the SKIT tool can generate optimized kinetic parameters, ensuring accurate modeling and effective scaling management. This flexibility makes the SKIT tool a versatile solution for addressing diverse scaling challenges in various production environments. Users can tailor the tool to their specific needs, optimizing the treatment strategies for both common and uncommon scales.

As we look to the future, SKIT is set to continually evolve, with plans already in motion to incorporate additional types of scales and scale inhibitors, including blends. This will significantly broaden the tool’s applicability across various oilfields and geothermal systems. The ongoing development of SKIT highlights OLI’s dedication to continuous innovation in scale prediction technologies. By expanding the range of scales and inhibitors that SKIT can model, we aim to provide even more robust and versatile solutions for managing scaling issues in diverse production environments. This forward-thinking approach ensures that SKIT remains at the cutting edge of scale management, delivering advanced capabilities to meet the evolving needs of the industry.

References:

- https://www.olisystems.com/resources/blog/enhancing-scale-risk-prediction-with-the-scale-kinetics-and-inhibitor-optimization-tool-in-scalechem-v12/

- Wang, A. Anderko, R. D. Young, A speciation-based model for mixed-solvent electrolyte systems, Fluid Phase Equilibria, 203, 1–2 (2002), pp. 141-176.

- Das, J. Kosinski, R. D. Springer, A. Anderko, Scaling risk assessment and remediation in geothermal operations using a novel theoretical approach, paper no. C2024-20701 (AMPP Conference 2024, New Orleans, Louisiana), pp. 1-15.